With the summer storm season already upon us, we know a lot of people are looking to fix up gutters and drainpipes around the house or workshop. This week alone, we’ve had a few people contact us looking for assistance with a sealant for HDPE pipework. This is a bit of a tricky application, so we thought we’d put together this quick guide.

The sections below cover why this job requires more than just any old adhesive, what we suggest for sealing and what we suggest for structural, high strength bonding work.

Why is HDPE Hard to Bond?

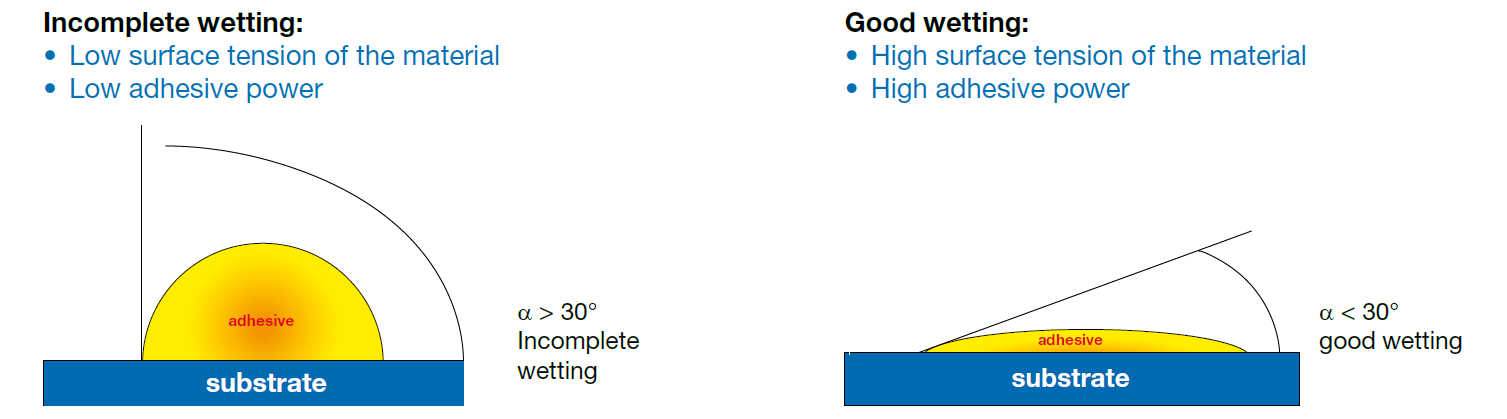

High density polyethylene (HDPE) is what’s known as a low surface energy plastic. All adhesives, no matter if they’re a super glue, epoxy or silicone, chemically react with the surface of the materials they are applied to in order to form a bond. Low surface energy materials make this reaction harder.

Other examples of low surface energy plastics include polypropylene, polyamide and, perhaps most notoriously of all, PTFE (aka Teflon).

What this means in practice is only certain types of glues will work with these materials.

Our Suggested Sealant for HDPE Pipes.

Our Suggested Sealant for HDPE Pipes.

If you’re looking for an elastic type of adhesive for sealing up around joins in HDPE drainage systems, our go to is our Aqua-Flex Underwater Adhesive. This adhesive sealant is an MS polymer and experience has shown us it works pretty well with HDPE.

This sealant will bond a little just by itself (though we really do stress the importance of roughening the surface first and cleaning). It will work much better in conjunction with our P400 Primer for polyolefins. Priming the surface first increases its surface energy, leading to a stronger bond with the Aquaflex.

Apart from the P400 Primer, Aqua-Flex doesn’t need any other special equipment. It’s available in three different colours ( black, white, grey) and can be dispensed using any standard caulking gun.

Our Suggested High Strength Adhesive of HDPE Pipe.

While Aqua-Flex is a great option for sealing connections and ductwork, it’s not what we suggest for making high strength joins. As an elastic adhesive, Aqua-Flex will always have a bit of flex to it and it is simply not designed for applications like joining a HDPE flange to pipe.

While Aqua-Flex is a great option for sealing connections and ductwork, it’s not what we suggest for making high strength joins. As an elastic adhesive, Aqua-Flex will always have a bit of flex to it and it is simply not designed for applications like joining a HDPE flange to pipe.

For these more demanding requirements, we suggest our Easy-Mix PE-PP 45 Acrylic Glue.

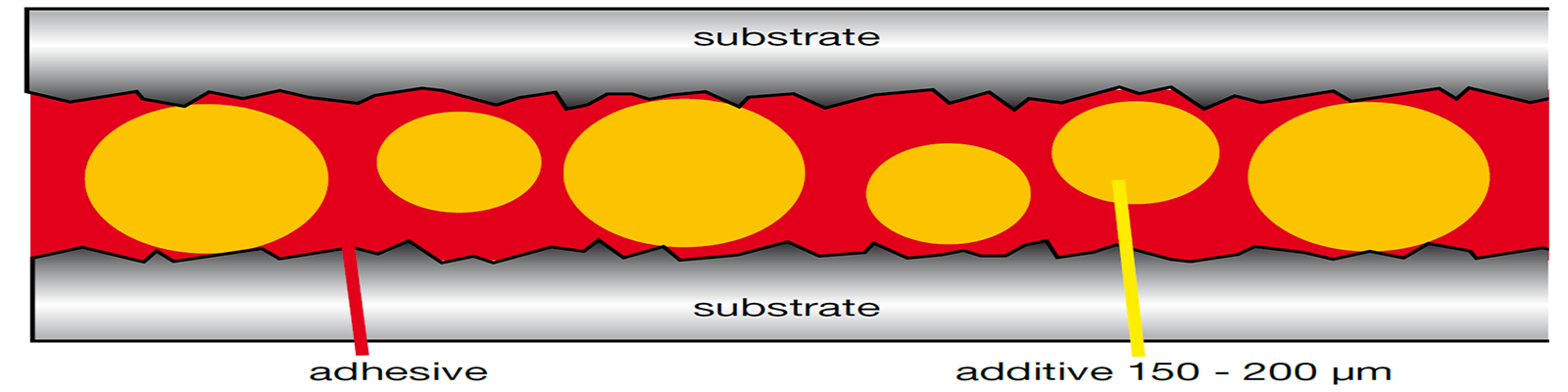

PE-PP 45 is an industrial-grade glue manufactured specifically for bonding polyethylene and polypropylene. Unlike (most) other acrylic glues, PE-PP 45 has a primer right there in it. This is not separate to the adhesive, rather, it is included within the contents and requires no separate process.

When PE-PP 45 has worked its way down the mixing nozzle and reaches the bonding surface, the primer will work to modify the structure to increase the surface energy. This makes bonding possible.

For the primer to work, a bonding gap of 0.15mm to 0.2mm is required. Fortunately, this is ensured through the presence of tiny glass beads in the mixture which ensure that the two bonding surfaces are forced no closer than this. In this way, you can prime and glue in one simple action.

PE-PP 45 isn’t cheap, but it works and works very well. It is used all over the world and has proven time and time again to be a viable and economical alternative to plastic welding for making these sorts of high strength joins.

This isn’t just our opinion; it’s been tested rigorously. The attached brochure details the tests conducted by the University of Northumbria in Newcastle (England) for this precise application. The results were exceptional and further validated PE-PP 45 as a real alternative to electrofusion welding for plastic gas pipes.

General Tips for Gluing HDPE (and everything really).

No matter what materials you’re looking to bond, there’s a few things to keep in mind.

- Whenever practical, roughen the surface that you’ll be applying the adhesive to. The larger the surface area available for a glue to stick to, the higher the practical strength. Roughening up (even just a very light sanding) significantly increases surface area and, therefore, final bond strength.

- Clean the surfaces before bonding. By their very nature, glues stick to whatever they meet. If there’s dust, dirt, or debris on the surface, they’ll stick to that rather than the intended surface. Proper cleaning prior to applying the glue is perhaps the most frequently overlooked step we hear about when working out why a bond may have failed.

More Information?

(A Lot) More information on both our Aqua-Flex Adhesive Sealant and our Easy-Mix PE-PP 45 Acrylic Adhesive is available on their dedicated product pages. Both are available online to purchase as well and ship anywhere in Australia.

If you do have further questions though, please do contact us. We’ll be happy to assist in any way we can.