One of our customers owns a Rail Freight Carriage, manufactured in 1954. It was damaged by a large tree falling across the roof. The roof structure held up well, but the rubber sheeting used on the carriage roof suffered some damage.

The customer wanted to do a patch repair job, rather than having to replace all the rubber sheeting. They were looking for an adhesive that was fast curing, moisture resistant and able to withstand temperatures under 0°C to +40°C.

The choice was our Weicon VA 250 Black High Viscosity, High Heat Rubber Filled Super Glue, along with our Neoprene Rubber Sheet. .jpg)

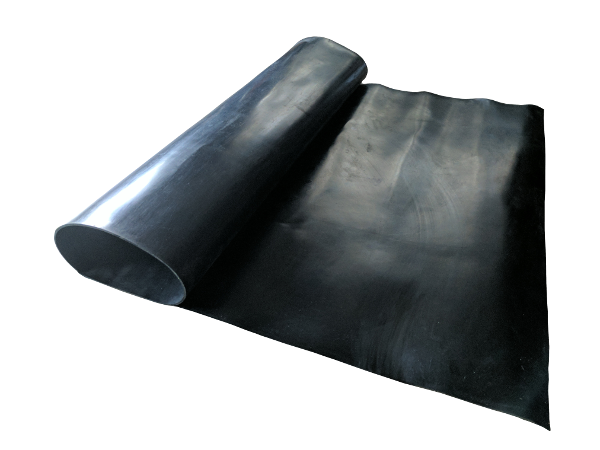

Neoprene Rubber Sheet

The Neoprene Rubber Sheet is an economical general-purpose rubber used for making seals, gaskets, lining strips, and bumpers. It also has good UV resistance, which is perfect for this job as the carriage is in the backyard.

Typical Applications for Neoprene Rubber

- Seals and gaskets for water pipes and tanks.

- Oil seals and gaskets.

- Sealing strips.

- Rubber floor matting.

- Sealing refrigeration fluids.

- Bumpers and protective linings.

- Automotive gaskets.

- Marine gaskets.

- Drain and roof join sealing. .

VA 250 Black High Viscosity, High Heat Rubber Filled Super Glue

The VA 250 Super Glue is a specialised type of super glue that is black in colour as it is rubber filled. This rubber filling enables VA 250 to provide good residual elasticity after curing and makes it particularly suitable for use in high or rapidly changing humidity and has excellent heat resistance (140°C).

VA 250 Material Compatibility.

|

Metal |

Compatible |

|

Plastic |

Highly Compatible (High Surface Energy and Medium Surface Energy Plastics Only) |

|

Rubber |

Highly Compatible |

|

EPDM Rubber |

Compatible |

|

Balsa Wood |

Compatible |

|

Glass/Ceramic |

Compatible |

|

Leather |

Compatible |

Applications for VA 250 Black Super Glue.

- Bonding of different rubber materials such as Neoprene, Natural, Nitrile.

- Making high strength rubber O Rings from rubber O Ring Cord.

- Securing rubber sponge and foam.

- Making metal to plastic and plastic to plastic joins.

- Bonding leather and other slightly porous materials.

- Creating high temperature resistant bonds.

- Bonding and gluing for applications that require good humidity resistance.

Preparation

-

The surface was roughened with some coarse sandpaper and the area was cleaned with a Surface Cleaner to remove dirt and debris.

-

The VA 250 Black High Viscosity, High Heat Rubber Filled Super Glue was applied easily as it comes in a pen and is high viscosity (less runny) so made applying to a sloped surface easy

-

The Neoprene patch was applied to the adhesive and then left to dry.

The customer was happy as he only needed to use it sparingly and had some left over for some patch jobs he has to do on the tubes and tyres of his firewood trolley.