Our Epoxy Repair Sticks are fast, simple and incredibly effective. Designed for quick patches that last, these epoxy putties are very easy to use and require no special equipment. There are 9 different types of Repair Stick in our range. In this buying guide, I will explain where these putties are used, how to choose the best one for your task, and a few tricks to help you get the very best result.

Before We Begin, Is A Repair Stick Right for You?

If you need an epoxy glue, a pourable epoxy resin for casting or filling, or an epoxy putty that will cover a large area (e.g. a 50mm / 75mm channel); Epoxy Repair Sticks are probably not the best solution.

They’re versatile enough you could probably make it work in a pinch, but there are other options that may better suit those jobs. We do have those options too, they're just not addressed in this guide to repair sticks and I don’t want to waste your time having you read about a less than optimal solution. For everyone else, please do read on.

Where Repair Sticks Are Used

One of the benefits of epoxy putties is that they are so versatile. They can be shaped and moulded into practically anything and then set hard to form a permanent solution. They also bond well to a large range of surface types and there’s no need to worry about fastening or securing them.

Repair Sticks take this versatility to the next level by making things even simpler. As a result, they are used in an incredibly broad range of repair and maintenance work all around the world. The Weicon Repair Stick range continues to be chosen for its combination of speed, performance, reliability and versatility. As the photos below will illustrate.

Weicon Epoxy Repair Sticks

Weicon Epoxy Repair Sticks

Weicon Repair Sticks are all two-part epoxy putties. They are designed for filling small gaps, reconditioning damaged surfaces, filling holes, replacing parts and bonding things together. Patching holes in steel or aluminium, replacing broken wooden parts, fixing cracks in concrete and sealing leaking pipes are all common applications.

They set hard and once they are set, can be machined, drilled, tapped and painted. This allows them to be used as part one of a two-part repair process, where the repair stick provides the new structure before a paint job, drilled hole or light sanding and makes it impossible to tell there was ever any damage in the first place.

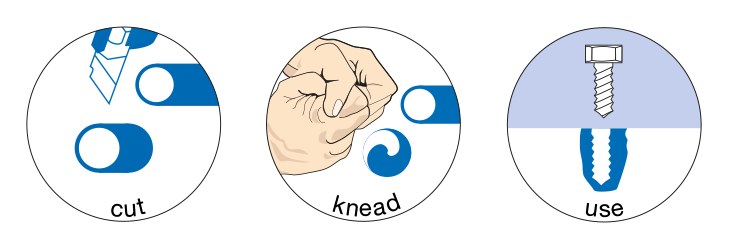

All Weicon Repair Sticks are supplied in plastic tubes. We’ll cover how best to use them in a little bit but it’s fair to say that this is very easy. Even though they are a two-part epoxy, both components are contained in a single sausage. This means there’s no measuring, just cut off the amount you require, knead and apply.

Because they are made from an Epoxy Resin base, all Weicon Repair Sticks share several common characteristics. Without getting too technical, some of these are included below:

| Feature | Value | Exceptions |

|---|---|---|

| Nature | Putty | None |

| Mixing Ratio by Volume | 1:1 | None |

| Fully (100%) Cured After (at 20°C) | 24 Hours | Plastic (36 Hours) & Titanium (72 Hours) |

| Maximum Gap Covering Power | 15mm | None |

| Continuous Temperature Resistance After Curing | -50°C to +120°C | Titanium (-50°C to +280°C) |

| Maximum Short-Term Temperature Resistance | +150°C | Titanium (+300°C) |

| Linear Shrinkage | Less Than 1% | None |

| Dielectric Strength | 3kV/mm | None |

| Available Pack Sizes | 57gm & 115gm | Wood (28gm & 56gm) |

It should also be noted that each grade of repair stick has the same chemical compatability as the others. A full compatability table is listed on the Technical Data Sheet for each individual grade which can be accessed from any one of the product pages. For convenience though, here's a link to the Technical Data on our Aluminium Repair Stick.

How to Use an Epoxy Repair Stick

One of the best things about Weicon Repair Sticks is how quick and simple they are to use. It can basically be summarised as cut, knead and apply. That said, to achieve the best possible bond there are a couple of extra little things to bear in mind. Cleaning the surface first is really important for making sure the repair stick bonds. The videos below demonstrate how to use a repair stick.

Choosing a Repair Stick

Choosing a Repair Stick

Above I focused on the many things that all 9 types of Repair Stick have in common. There’s also a lot that sets each type apart. Depending on where and what you are using a repair stick for, these features could be critical or thoroughly unimportant. It really does depend.

The below sections detail some of the main points of difference for the Weicon Repair Stick Range.

Repair Sticks – Material Compatibility for Each Type

| Repair Stick Type | Concrete | Aluminium | Aqua | Copper | Plastic | Stainless Steel | Steel | Titanium | Wood |

|---|---|---|---|---|---|---|---|---|---|

| Metal (e.g. stainless steel, brass, cast iron, aluminium) | + | ++ | ++ | ++ | + | ++ | ++ | ++ | + |

| Hard Plastics* (e.g. epoxy laminates, rigid PVC) | + | + | ++ | + | ++ | + | + | + | + |

| Wood (e.g. oak, beech, spruce, balsa) | + | + | + | + | + | + | + | + | ++ |

| Derived Timber Products (e.g. plywood, MDF) | + | + | + | + | + | + | + | + | ++ |

| Fibre Reinforced Materials (e.g. GFRP, CFRP, Fibreglass) | + | + | + | + | ++ | + | + | + | + |

| Glass, Ceramics | + | + | ++ | + | + | + | + | + | + |

| Stone (e.g. granite, brick, concrete, marble) | ++ | + | ++ | + | + | + | + | + | + |

| Rubber Elastomers | - | - | - | - | - | - | - | - | - |

++ = Highly Compatible

++ = Highly Compatible

+ = Compatible

- = Not Compatible

*Performance will vary depending on the exact type of plastic being bonded. Generally, low surface energy plastics will be much harder to bond to than high surface energy (such as rigid PVC).

Colour (After Curing)

If you don't plan on painting the cured repair stick, its colour after curing can be quite important. The table below summarises what you can expect.

| Type of Repair Stick | Colour (Once Cured) |

|---|---|

| Aluminium | Aluminium |

| Aqua | White |

| Concrete | Concrete Grey |

| Copper | Copper |

| Plastic | Light Blue |

| Stainless Steel | Grey |

| Steel | Dark Grey |

| Titanium | Grey-Green |

| Wood | Light Beige |

Technical and Performance

| Repair Stick Type | Aluminium | Aqua | Concrete | Copper | Plastic | Stainless Steel | Steel | Titanium | Wood |

|---|---|---|---|---|---|---|---|---|---|

| Filler Type for Epoxy Resin Base | Aluminium | Ceramic | Ceramic | Copper | Plastic | Stainless Steel | Metal | Titanium | Mineral |

| Pot Life In Minutes (25gm @ 20°C) | 4 | 15 | 6 | 3 | 20 | 4 | 4 | 70 | 15 |

| Handling Strength in Minutes (35%, 20°C) | 10 | 30 | 15 | 10 | 40 | 10 | 10 | 120 | 45 |

| Mechanical Strength in Minutes (50%, 20°C) | 60 | 60 | 60 | 60 | 180 | 60 | 60 | 480 | 60 |

| Final Strength in Hours (100%, 20°C) | 24 | 24 | 24 | 24 | 36 | 24 | 24 | 72 | 24 |

| Pressure (DIN 53281-83) N/mm² | 75 | 65 | 80 | 80 | 65 | 75 | 75 | 80 | 70 |

| Shore Hardness D | 75 | 65 | 80 | 80 | 65 | 75 | 75 | 80 | 70 |

| Average Tensile Shear Strength After 7 Days @ 20°C (DIN 53283) N/mm² |

Aluminium (Sandblasted) |

Steel Sandblasted) |

Concrete | Copper (Sandblasted) |

PVC (Sanded) |

Stainless (Sandblasted) |

Steel (Sandblasted) |

Steel (Sandblasted) |

Beech (Sanded) |

| 4.2 | 6.2 | 4.8 | 4.8 | 2.4 | 3.9 | 4.1 | 5.1 | 6.2 | |

| Special Features / Approvals | Excellent For Aluminium |

Cures Underwater |

Matches Concretes Appearance |

NSF Approved |

NSF Approved |

NSF Approved | NSF Approved |

High Temp. Hard Weaing |

Same Density As Wood |

NSF Approved = Clearance Certificate for Direct Use In The Food Industry according to NSF/ANSI (Standard 61).

More Information on Repair Sticks

More information on each of the individual grades of Weicon Epoxy Repair Sticks can be found on their respective product pages (linked via the images below). Alternatively, please do not hesitate to contact us here at Swift Supplies with any questions you have about our repair stick range. We've been working with these for years now and we are very happy to assist.

Stay Up To Date With Our Buying Guides

We hope you enjoyed this post on our epoxy repair sticks. If you would like to stay up to date as we continue to publish new buying guides, and update our existing ones as we think of extra bits of information or new products are released, we really hope you’ll sign up for our newsletter.

We’ll always keep you in the loop with the latest developments, new product releases and information.