Sigraflex Universal Tanged Graphite Gasket Sheet - 1.5mm Thick x 1500mm Square

BULK DISCOUNT RATES

| Buy 3 - 4 | and pay only $629.27 each |

| Buy 3 - 4 | and pay only $629.27 each |

Our Sigraflex® Universal is a high-quality grade of Tanged Graphite Stainless Steel Reinforced Gasket Sheet used for demanding sealing applications. This gasket material has excellent temperature resistance as well as the ability to withstand very high sealing pressures (Vacuum to 100 Bar).

Produced by SGL Carbon, this material is often used for high pressure automotive or marine gaskets, high temperature flange gaskets in the energy sector and for gaskets used in the food processing, petrochemical, oil & gas, heating, chemical processing and mining industries.

The sections below provide more information on this graphite gasket material while the Specifications Tab and Media tab also contain more information on its technical properties.

One of the most common factors leading to the specification or selection of our Tanged Graphite Gasket Material is temperature. Gaskets made from our Sigraflex Universal are able to withstand temperatures down to -250°C and as high as 550°C depending on the media type being sealed.

For temperatures over 450°C it is suggested that an engineering appraisal be conducted first to determine suitability. This quality gasket material is highly resistant to thermal shock.

The Stainless-Steel Reinforcement in our Universal Tanged Graphite Sheet ensures this gasket material has excellent pressure resistance. Gaskets made from Sigraflex Universal are able to withstand operating pressures from vacuum up to 100 Bar.

This material has high blow-out resistance and excellent mechanical strength.

Special Production Method Ensures High Performance.

Special Production Method Ensures High Performance.This grade of tanged graphite is produced using a specialised process that combines the layers without the use of adhesives or binding agents. This helps to ensure good, consistent performance and reduces the chance of aging or embrittlement over time.

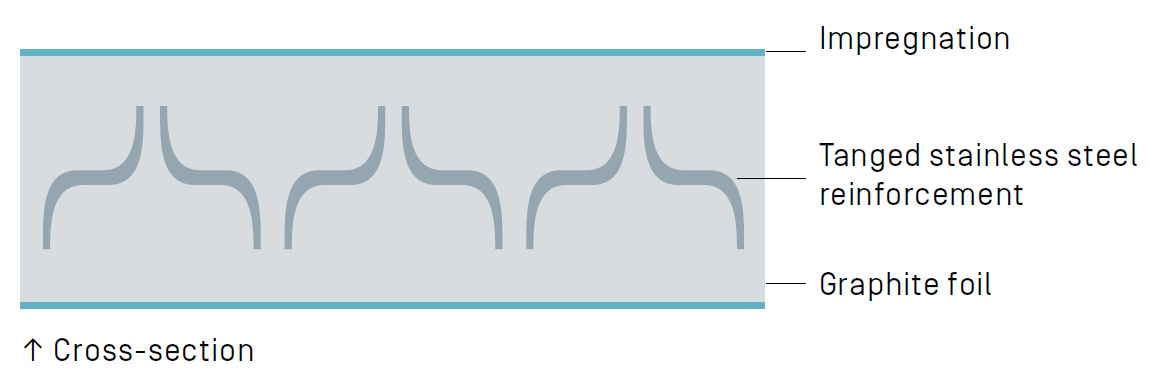

Sigraflex Universal Tanged Graphite is made from flexible graphite foil with one or two tanged 316L stainless-steel reinforcement layers. The sealing sheet is impregnated using a special methodology which reduces leakage and improves handling. Specifically, it gives the sheet a scratch resistant, anti-stick finish which assists with installation and gasket removal in the future.

Our Tanged Graphite Gasket Sheet exhibits very good long-term stability of compressibility and recovery. This performance holds up even when the gaskets are subjected to fluctuating temperatures to ensure long term, reliable sealing.

In addition, Sigraflex Universal Tanged Graphite Gaskets exhibit no measurable cold or warm flow characteristics up to the maximum permissible gasket stress (data on this is contained on the linked TDS). Our Tanged Graphite Sheet has a very low coefficient of friction and excellent residual stress.

Since they are produced from very high purity (98%) graphite, our Sigraflex Universal Tanged Graphite sheets offer exceptional chemical resistance. They are widely used for sealing many different types of corrosive media as well as steam, gases and more.

Sigraflex Universal Tanged Graphite is impermeable to gases & liquids. An inert material, it is also highly resistant to radiation.

Manufactured by SGL Carbon and used all around the world for demanding sealing applications, Sigraflex Universal has been subjected to and certified in accordance with numerous testing authorities. Some of the relevant approvals include:

This page lists our range of full sheets of Tanged Graphite. Our online store also has this quality gasket sheet in a number of other sheet sizes; links to each are included at the bottom of this page.

In addition to these standard sizes, we are also able to provide custom cut sheets, gaskets & seals made from steel reinforced gasket material. To enquire about a specific size, please do contact us.

| Colour | Black | ||||

| Property | Units | ||||

| Thickness | 1 | 1.5 | 2 | 3 | mm |

| Bulk Density of Graphite | 1 | 1 | 1 | 1 | g/cm³ |

| Ash Content of Graphite | ? 2.0 | ? 2.0 | ? 2.0 | ? 2.0 | % |

| Purity | ? 98 | ? 98 | ? 98 | ? 98 | % |

| Total Chloride Content | ? 25 | ? 25 | ? 25 | ? 25 | ppm |

| Total Halogen Content | ? 70 | ? 70 | ? 70 | ? 70 | ppm |

| Total Sulphur Content | < 300 | < 300 | < 300 | < 300 | ppm |

| Oxidation Rate in Air at 670°C (TGA) |

< 4 | < 4 | < 4 | < 4 | % / h |

| Oxidation Inhibitor | Yes | Yes | Yes | Yes | - |

| Tanged Stainless Steel Sheet Details | |||||

| ASTM Material Number | 316 (L) | 316 (L) | 316 (L) | 316 (L) | - |

| Thickness | 0.1 | 0.1 | 0.1 | 0.1 | mm |

| Number of Sheets | 1 | 1 | 1 | 2 | - |

| Gasket Factors (DIN E 2505 / DIN 28090-1) See Technical Data Sheet |

|||||

| Compressibility (? KSW) | 35 | 40 | 40 | 40 | % |

| Recovery at 20°C (?KRW) | 5 | 5 | 5 | 5 | % |

| Hot Creep (?WSW) | < 4 | < 4 | < 4 | < 4 | % |

| Recovery at 300°C (?WRW) | 4 | 4 | 4 | 4 | % |

| E-Modul 20 N/mm² (DIN 28090-1) | 850 | 850 | 850 | 850 | N/mm² |

| Compressibility (ASTM F36) | 35 | 40 | 40 | 40 | % |

| Recovery (ASTM F 36) | 15 | 12 | 12 | 12 | % |

| ASME Code Sealing Factors | |||||

| M Factor | 2.5 | 2.5 | 2.5 | 2.5 | - |

| Y Factory | 2000 | 2000 | 2000 | 2000 | - |

| SKU | SWM000283B01 |

|---|---|

| Brand | SGL Carbon |

Technical Data Sheet.

|

||

| Tanged Graphite Stainless Steel Reinforced Gasket Sheet Technical Data Sheet |

Related Content & Information.

| Tanged Graphite - Quick Reference Guide |