If you have found your way to this article, you are most likely trying to decide on the best sponge or foam material for your project. "Sponge" and "Foam" are the generic names that are given to the many varieties of expanded rubber products that range from the humble kitchen sponge to the highly technical insulation used in the walls of planes and rocket ships.

The first and most major decision you will have to make is whether your application requires an open-cell or closed-cell foam. Each type has their own very unique characteristics and properties.

This article will explain what they are, what difference they make as well as give you a bit more information on the types we sell.

There are many types of foam on the market.

All Sponge and Foam Products are made up of "Cells"

Sponge and Foam materials are rubber compounds that have been subjected to a gas or inflating agent under high pressure. The effect of this is to expand the rubber by creating hollow bubbles within the structure of the material known as "cells". The size of these cells will not only impact the density of the sponge, but whether they are open or closed has a major impact on many of the technical properties of the material. Read on to find out how.

|

|---|

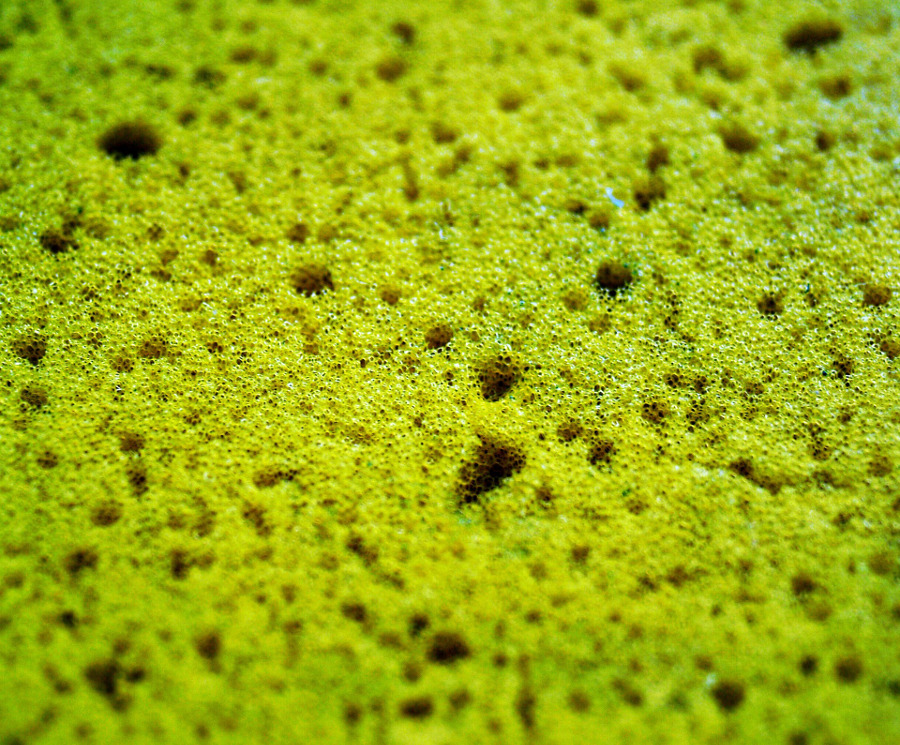

| Close-up of Open Cell Sponge Surface. |

Open-cell Sponge and Foam

Open cell foams are characterized by cells that are not fully closed.

They do not have to all be open (sponges are available with a mix of both), however as a rule if more than 50% are open then the sponge is classified as open cell. This has several implications.

Firstly, it means that they are generally less dense (more squishy) than closed cell sponges. It also means that they are not water or air tight and allow whatever liquid or gaseous media to which they are exposed to pass through, making them poor for sealing applications. Because less materials are used in their construction however, they are also generally more economical than their closed-cell counterparts.

Uses for Open-cell Foam

|

|---|

| Close-up of Open Cell Sponge Surface. |

Because open-cell foams are generally less dense then closed-cell foams, they are often used for applications requiring comfort such as internal cushions, car seats and sofa's. They are also popular for use as mattresses and pillows as they allow air to pass through keeping them cool. Because they hold and release water they are also commonly used for kitchen sponges, mop heads and other cleaning products.

Open cell foams are also often used as filter materials, as the amount and size of open-cells can be varied allowing the flow of air or water that passes through to be controlled at varying rates. Open-cell foams are also used in acoustic applications as they are noise permeable. Soundwaves travel into them and are absorbed in the open cell structure rather than bouncing off.

Types of Open-cell Foam

There are many different varieties of Open-cell foam on the market and each is generally suited to a specific application. I.e. Sponge Foam, Upholstery Foam, Filter Foam, Acoustic Foam. If you are after these types of foams they are readily available on the internet. Simply google the type you are after and you will find plenty of suppliers.

|

|---|

| Closed Cell Foam Sheets and Cutting Equipment. |

Closed-cell Sponge and Foam

As you might have guessed by now, closed cell foams consist of cells that are completely closed, making them great for sealing and insulation. Generally, when compressed around 10-25% of their total thickness, they become watertight. Closed cell foams can be manufactured in a range of densities and because of their durability are also great for protective applications. Closed cell foams are more resistant to water degredation and their higher density prevents mould growth.

Closed-cell foam is by far and away more popular for commercial, industrial and home repair and DIY uses. Which is why at Swift Supplies, we offer several types of this material.

Uses for Closed-cell Foam

Because they are air and water-tight, closed-cell foams are great for sealing and gasketing applications. They are often used to make seals for electrical boxes and other cabinetry that requires waterproofing. They also seal from dust and draught so can be used in door and window applications and also many sealing applications within automobiles. They are even used for sealing in air conditioning and other HVAC applications. Closed-cell foams are also good for insulation as their cells don't allow air to pass through, forming an air barrier. This makes them an effective insulator.

Types of Closed-cell Foam

There are many types of closed cell foams on the market, these include PVC Foam, EPDM Foam, Neoprene Foam and Polyethylene Foam. Swift Supplies offers several choices of closed cell foam. Our Neoprene foam is available in sheet (without adhesive backing) or tape form. It's strong, durable, heat and chemical resistant and flame retardant. It also meets motor vehicle safety standards (FMVSS302) so is the foam tape of choice for automotive applications. To find out more about this

sheet (without adhesive backing) or tape form. It's strong, durable, heat and chemical resistant and flame retardant. It also meets motor vehicle safety standards (FMVSS302) so is the foam tape of choice for automotive applications. To find out more about this

tape you can check out this video.

For a more economical closed cell foam we offer our PVC foam tape. It's lightweight but resistant to many weathering influences like UV and Ozone, making it useful for both indoor and outdoor applications.

There are many more varieties on the market, if you want to talk about which one might be the best for you then give us a call.

| Open Cell Foam | Closed Cell Foam |

| Retains & releases water. | Watertight and airtight. |

| Generally Less Dense. | More dense and |

| Lower Mechanical Strength and durability. |

Durable and resistant to tear. |

| Good for comfort and support applications. |

Good for gasketing applications |

| Cleaning, Upholstory and Filtering Applications. |

Sealing, Insulating and Protective Appications. |