- High temperature resistant gaskets for AS 2129 flanges.

- Suitable for use with potable water.

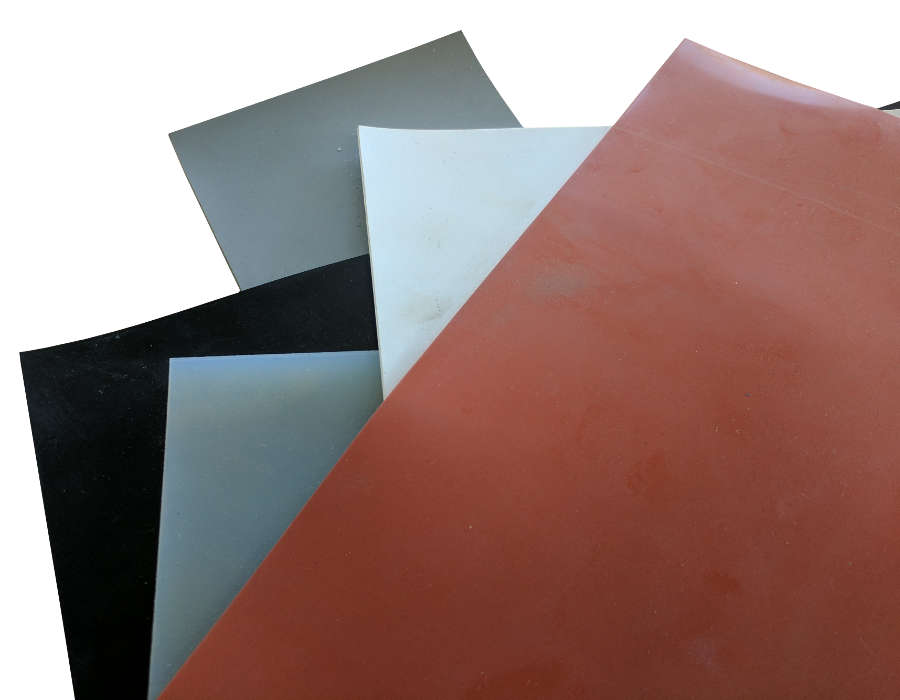

- Made from industrial-grade silicone rubber.

- Cut to size in our Australian facilities to suit the precise requirements of AS 2129.

Silicone Rubber Gaskets are a popular choice for sealing flanges in applications with elevated temperatures.

This page lists our range of 3mm thick Red Silicone Gaskets to suit AS 2129 flanges in the Full Face configuration. They are quality rubber gaskets, cut to size in Australia, with a maximum operating temperature of 260°C and a range of other performance benefits.

The sections below cover the available sizes, performance capabilities of this material and more.

Sealing Capabilities of Red Silicone Rubber Gaskets.

Our Red Silicone Rubber is a premium-quality, industrial grade Silicone Rubber Sheet with excellent sealing properties. This rubber has excellent temperature resistance, very good electrical insulation properties and wide-ranging chemical resistance. These, and other properties, are expanded on more below:

Food Grade and Potable Water Approved.

Washers, gaskets and seals cut from our Red Silicone Rubber inherit this materials food and potable water certification. Red Silicone Rubber Gaskets from Swift are made from food grade rubber which allow them to be used in sealing equipment that will have direct contact with food (as per FDA and EU standards) and for sealing potable (drinking) water (as per WRAS).

This rubber also carries certifications for several other applications which are detailed more on the attached technical data and over on the specifications tab.

Excellent Heat and Cold Temperature Resistance.

Seals made from our Red Silicone Rubber will withstand ongoing exposure to temperatures between -60°C and +230°C as well as short-term spikes to 250°C.

This is important as most other rubbers (Viton/FKM is the other exception) simply will become brittle and crack well before -50°C and will exhibit serious degradation before 160°C. Silicone doesn't and maintains excellent flexibility and sealing performance. An important attribute for high or low temperature seals.

Excellent Sealing Characteristics.

Silicone Gaskets are often selected because of this rubber excellent sealing performance. All the gaskets featured on this page are made from 60 Shore A Durometer Rubber sheet and have excellent compression, recovery and mechanical strength.

This results in flange gaskets which are very long lasting and offer reliable sealing performance.

Flange Gaskets to Suit AS2129 Sizing Info.

The gaskets featured on this page are the full-face style of rubber flange gasket. These gaskets take up the full face of the flange, with holes cut for the bolts. Both ring and full-face gaskets can be used on these flanges depending on particular requirements and user preferences.

AS 2129 Flanges are most commonly found in either AS 2129 Table D or AS 2129 Table E which is why gaskets for both are listed here. That said, there are quite a few other tables made and gaskets for these (e.g. Table A, C, F, H) can also be produced upon request.

Why are some Table D and Table E Gaskets the same size while others aren’t?

The AS 2129 Flange Specification is like many others (e.g. ANSI 150) in that many of the smaller sized flanges (and consequently, gaskets) are the same across tables. In the AS 2129 Spec, gaskets made to suit flanges with a nominal bore of up to 80NB are the same no matter if the flanges are listed as Table D or Table E. After this, sizes do differ.

The table below provides more specifics on this.

AS 2129 Table D Gaskets Sizing.

All Dimensions below are given in millimeters (mm).

Flange Nominal

Bore |

Gasket OD |

Gasket ID |

Number of

Holes |

Hole

Diameter |

PCD |

Matches

Table |

| 15NB |

95 |

17 |

4 |

14 |

67 |

E |

| 20NB |

100 |

22 |

4 |

14 |

73 |

E |

| 25NB |

115 |

25 |

4 |

14 |

83 |

E |

| 32NB |

120 |

32 |

4 |

14 |

87 |

E |

| 40NB |

135 |

40 |

4 |

14 |

98 |

E |

| 50NB |

150 |

50 |

4 |

18 |

114 |

E |

| 65NB |

165 |

68 |

4 |

18 |

127 |

E |

| 80NB |

185 |

82 |

4 |

18 |

146 |

E |

| 90NB |

205 |

90 |

4 |

18 |

165 |

- |

| 100NB |

215 |

100 |

4 |

18 |

178 |

- |

| 125NB |

255 |

125 |

8 |

18 |

210 |

E |

| 150NB |

280 |

150 |

8 |

18 |

235 |

- |

| 200NB |

335 |

200 |

8 |

18 |

292 |

- |

| 250NB |

405 |

250 |

8 |

22 |

356 |

- |

| 300NB |

455 |

300 |

12 |

22 |

406 |

- |

| 350NB |

525 |

350 |

12 |

26 |

470 |

E |

| 400NB |

580 |

400 |

12 |

26 |

521 |

E |

| 450NB |

640 |

450 |

12 |

26 |

584 |

- |

| 500NB |

705 |

500 |

16 |

26 |

641 |

E |

| 600NB |

825 |

600 |

16 |

30 |

756 |

- |

AS 2129 Table E Gaskets Sizing.

All Dimensions below are given in millimeters (mm).

Flange Nominal

Bore |

Gasket OD |

Gasket ID |

Number of

Holes |

Hole

Diameter |

PCD |

Matches

Table |

| 15NB |

95 |

17 |

4 |

14 |

67 |

D |

| 20NB |

100 |

22 |

4 |

14 |

73 |

D |

| 25NB |

115 |

25 |

4 |

14 |

83 |

D |

| 32NB |

120 |

32 |

4 |

14 |

87 |

D |

| 40NB |

135 |

40 |

4 |

14 |

98 |

D |

| 50NB |

150 |

50 |

4 |

18 |

114 |

D |

| 65NB |

165 |

68 |

4 |

18 |

127 |

D |

| 80NB |

185 |

82 |

4 |

18 |

146 |

D |

| 90NB |

205 |

90 |

8 |

18 |

165 |

- |

| 100NB |

215 |

100 |

8 |

18 |

178 |

- |

| 125NB |

255 |

125 |

8 |

18 |

210 |

D |

| 150NB |

280 |

150 |

8 |

22 |

235 |

- |

| 200NB |

335 |

200 |

8 |

22 |

292 |

- |

| 250NB |

405 |

250 |

12 |

22 |

356 |

- |

| 300NB |

455 |

300 |

12 |

26 |

406 |

- |

| 350NB |

525 |

350 |

12 |

26 |

470 |

D |

| 400NB |

580 |

400 |

12 |

26 |

521 |

D |

| 450NB |

640 |

450 |

12 |

26 |

584 |

- |

| 500NB |

705 |

500 |

16 |

26 |

641 |

D |

| 600NB |

825 |

600 |

16 |

33 |

756 |

- |