TD1150 Transformer Grade Rubberised Cork 1.5mm Thick x 915mm Square

BULK DISCOUNT RATES

| Buy 5 or above | and pay only $53.15 each |

| Buy 5 or above | and pay only $53.15 each |

TD1150 Transformer Grade Rubberised Cork is a high rubber content cork designed specifically for electrical apparatus sealing. This specialised cork gasket sheet is made from a specialised Nitrile rubber (NBR) combined with small cork granules.

It is highly compatible with most common transformer fluids and exhibits excellent compressive strength, strength and flexibility. It also has good electrical insulation properties and is very durable.

This high quality grade of Cork / Rubber Sheet measures 3mm Thick x 915mm Wide x 915mm Long.

More information on the various characteristics of this cork sheet is included below:

TD1150 is widely used for making cork gaskets & seals. In many ways, it is quite similar to our TD1049 Premium Grade Cork as they are both made with a Nitrile rubber binder. The (primary) difference is in the amount of rubber in the finished sheet with TD1150 having a far higher rubber content.

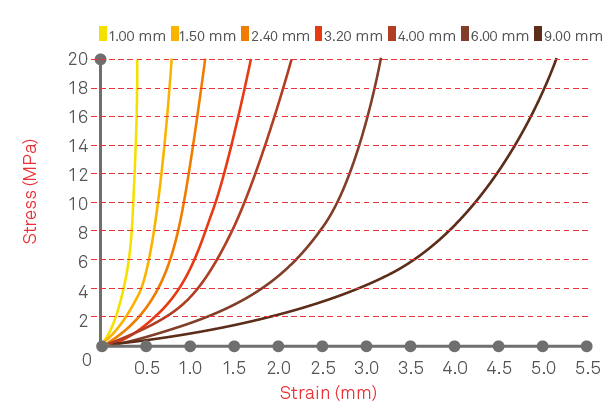

This high percentage of rubber ensure this cork has very good elongation (100% max.) and compressive strength (exceeds 70 MPa). It has a shore durometer hardness of 70 Shore A and a broad sealing stress range (3 MPa to 20 MPa).

|

|

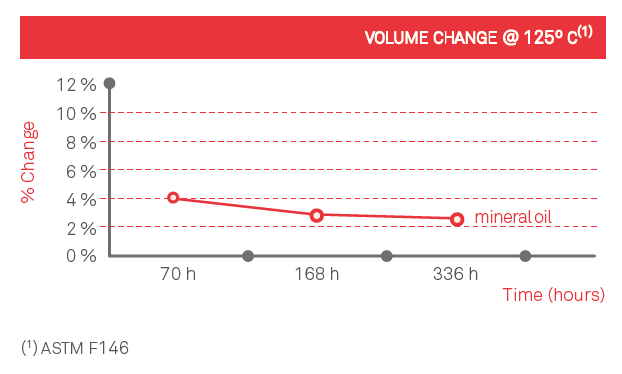

Used all around the world for electrical bushings and gaskets, TD1150 has been tested in conjunction with a variety of transformer fluids. A summary of this cork sheets fluid compatibility is included below:

| Fluid Contact | |

| Mineral Oil | Recommended |

| Natural Ester Oil | Recommended |

| Silicone Oil | Recommended |

| SF6 Gas | Suitable |

Results According to:

ASTM D3455: Test Methods for Compatibility of Construction Materials with Electrical Insulating Oil of Petroleum origin.

&

ASTM D5282: Test Methods for Compatibility of Construction.

In addition to the transformer fluids listed above, this cork sheet is also highly compatible with all liquids and media that Nitrile can usually handle. These include air, water, alcohols, fuel, diesel oils, glycol and more. Our Rubber Chemical Compatibility Guide has a far longer list.

This high-quality cork is manufactured by Amorim and used all around the world. By far, the most common application for TD1150 is making cork gaskets and seals for transformers and electrical devices.

It is also used for making electrical bushings and in a variety of applications outside of the electrical industry including pipe support liners and general-purpose cork gaskets.

| Colour | Black |

|---|---|

| Continuous Operating Temperature | -30°C to 125°C |

| Binder Type | Nitrile Butadiene Rubber (NBR) |

| Compatible with Oil | Yes |

| Compatible with Fuel | Yes |

| Compatible with Mineral Oil | Yes |

| Compatible with Natural Ester Oil | Yes |

| Compatible with Silicone Oil | Yes |

| Compatible with SF6 Gas | Yes |

| Hardness | 70 Shore A (ASTM D2240) |

| Tensile Strength | 2.5 MPa (ASTM D412, Die C) |

| Density | 1,100 kg/m³ (ASTM D297) |

| Elongation | 100% (ASTM D412, Die C) |

| Volume Resistivity Ρ (Ώ.cm) | 2.1 x 1010 (ASTM D257, 23°C, 50% RH, 500V dc. |

|

SEALING STRESS lt is very useful when making material selections to meet lf you require LD data at a different thickness, just ask us. |

|

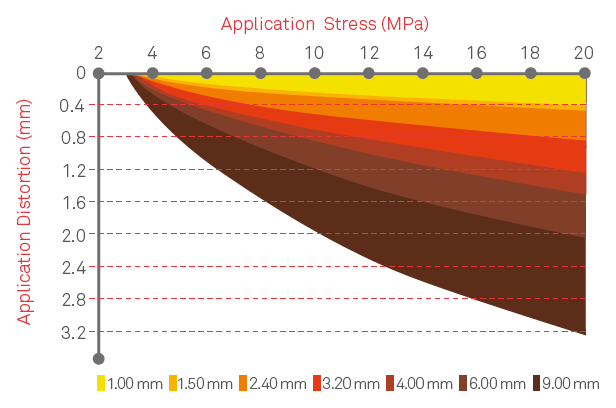

SYSTEM DISTORTION. At a given sealing stress a corresponding maximum allowable flange distortion assures that a “positive seal” is guaranteed for a defined material thickness. By intersecting the hardware distortion and the respective sealing stress, a suggested material thickness is selected. However it is always recommended to validate the material thickness in your system due to unexpected flange distortion behaviour. |

| SKU | SWM000309B01 |

|---|---|

| Brand | Amorim |