BULK DISCOUNT RATES

| Buy 3 - 5 | and pay only $43.13 each |

| Buy 6 or above | and pay only $40.47 each |

| Buy 3 - 5 | and pay only $43.13 each |

| Buy 6 or above | and pay only $40.47 each |

RK-1300 Two-Part, No-Mix, High Strength Acrylic Glue is a high strength construction adhesive based on methyl methacrylate (MMA). It has a party consistency and is used to create very high strength bonds that have high impact, peel and shear strength.

RK-1300 is particularly well suited for joining larger surface areas. It works very well with metal (including both passive and active styles) and is also compatible with many types of rigid plastics (such as acrylic, polycarbonate and fibreglass) as well as ceramics and ferrites.

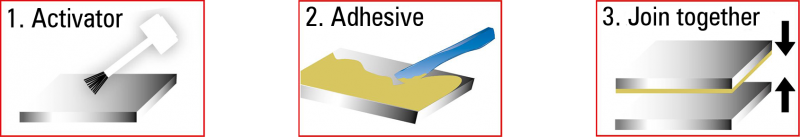

This industrial grade acrylic glue is very easy to use (the demo video shows this). Though it is a two-part adhesive, there’s no mixing or measuring involved. For close fitting joins (i.e. those with a bonding gap of 0.4mm or below), simply apply the activator to one side and spread.

Once done, apply the pasty glue to the other and join the two parts (for larger bonding gaps up to 0.8mm, apply the activator to both sides). The parts should be left seperate for at least 5 minutes before they are joined.

Once the two bonding surfaces have been joined, the adhesive will set fast. At a room temperature of 20°C, RK-1300 Acrylic Glue achieves 35% cure in just 5 minutes and hits 50% of its final strength after 9 minutes. It will be fully cured within 24 hours.

One additional benefit of the adhesive + activator “No Mix” process used with this glue is time. Parts coated with just the adhesive can be stored for up to 30 days (at room temperature) without losing effectiveness. This could be a real benefit for anyone with multiple parts to bond as they can prep multiple items with just the adhesive before proceeding to apply the activator and join sequentially.

Manufactured in Germany by Weicon, this high strength acrylic glue is able to withstand permanent exposure to temperatures up to 130°C (and as low as -50°C) once fully cured. It will also tolerate short-term spikes to +180°C. It has a beige colour after it is cured.

For more technical information on this high quality industrial strength acrylic adhesive, and details on surface pre-treatment and processing, we really do suggest consulting our RK-1300 Two-Part, No-Mix High Strength Acrylic Glue Technical Data Sheet.

Because of its combination of very high strength, material compatibility and versatility in how it is applied, RK-1300 Acrylic Glue is used in a variety of industries and applications around the world. These include:

Please note Polyamide, PTFE and polyolefin may only be bonded after special treatment of the surface (e.g. low-pressure plasma, corona, flame impingement).

| Basis | Methyl Methacrylate (MMA) |

|---|---|

| Colour After Curing | Beige |

| Density of the Mixture | 1.2 g/cm³ |

| Viscosity of the Mixture | 21,000 MPa |

| Application Procedure | No Mix |

| Composition | Pasty |

| Handing Strength (35% of Final) | 6 Minutes |

| Capable of Bearing Mechanical Loads (50% of Final) |

9 Minutes |

| Processing Temperature | +10°C to +40°C |

| Curing Temperature | +18°C |

| Fully Cured (100%) | 24 Hours |

| Adhesive Gap Bridging | 0.4mm – 0.8mm |

| Temperature Resistance (After Curing) |

-50°C to +130°C (+180° Short-Term) |

| IMPA Code | 81 29 91 |

| ISSA Code | 75.629.52 |

| Shear Strength (According to DIN 53281) | |

| Aluminium | 20 N/mm² |

| Sand Blasted Steel | 25 N/mm² |

| Stainless Steel | 25 N/mm² |

| Polycarbonate | 10 N/mm² |

| PMMA | 9 N/mm² |

| ABS | 6 N/mm² |

| Hard PVC | 7 N/mm² |

| Fibreglass Reinforced Polyester | 16 N/mm² |

| Fibreglass Reinforced Epoxy | 24 N/mm² |

| Polyamide 6.6 | 2 N/mm² |

| SKU | SWM000221B01 |

|---|---|

| Brand | Weicon |