BULK DISCOUNT RATES

| Buy 3 - 5 | and pay only $44.29 each |

| Buy 6 or above | and pay only $41.30 each |

| Buy 3 - 5 | and pay only $44.29 each |

| Buy 6 or above | and pay only $41.30 each |

Our RK-1500 Two-Part, No-Mix, High Strength Liquid Acrylic Adhesive is a professional-quality structural adhesive used by a range of industries. Based on methyl methacrylate (MMA), this is a liquid form of acrylic glue that is ideal for large surface areas where it needs to be evenly spread.

Bonds made with RK-15000 Structural Acrylic are incredibly strong and long lasting. They exhibit high impact, peel and shear strength.

This acrylic adhesive is quite similar to our RK-1300 with the main difference being the consistency. Rk-1300 is a lot pastier and is a better choice for bonding vertical surfaces.

Manufactured in Germany by Weicon, RK-1500 is a high-performance MMA Adhesive with a variety of benefits and performance traits. These include:

You definitely don’t choose RK-1500 for temporary bonding. This acrylic glue cures to form extremely strong bonds that will last. It has been tested in accordance with DIN 53281 standards with a variety of materials leading to the following results:

RK-1500 MMA Adhesive is designed for permanently joining different types of materials. It works with a variety of different substrates and surfaces types, including:

*Please note Polyamide, PTFE and polyolefin may only be bonded after special treatment of the surface (e.g. low-pressure plasma, corona, flame impingement

One of the real benefits of RK-1500 is the cure speed you can expect. This feature makes it ideal for use in the construction or manufacturing sectors as well as anywhere else where structural adhesives are used in serial production.

Once the two-parts are united as the surfaces are joined (see below on this and it can be a great benefit) you can expect cure times to roughly be:

These times are somewhat dependent on bonding conditions and are estimated using an assumed working temperature of 20°C. Higher temps will accelerate curing while lower temps will have the opposite effect.

RK-1500 Acrylic Adhesive is designed for permanent bonding. Joints created with this high strength glue are very long lasting. They exhibit very good impact strength as well as excellent peel and shear strength. This makes them ideal for construction and structural bonding as they will withstand the rigours of demanding industrial requirements.

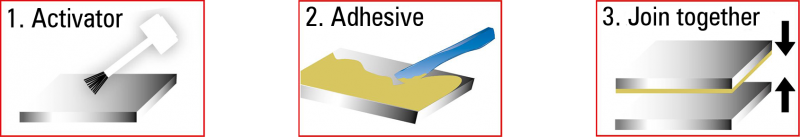

Weicon RK-1500 is a two-part acrylic adhesive made up of the liquid glue and a activator. There’s no mixing though. To use, you first determine if you need to coat one or both surfaces (this comes down to the bonding gap, up to 0.4mm just do one; up to 0.8mm it’s better to do both).

For close fitting parts (activator one side only) you would then apply the glue. Spread it out and let it sit.

One of the real benefits of RK-1500 is this can be done well ahead of time. In fact, we’ve often seen customers prepare multiple parts with the adhesive and leaving them sit. RK-1500, when used in this fashion, has no real pot life and parts can be stored for up to 30 days without losing effectiveness.

Once you’re ready to bond, coat the other bonding surface with the activator and join. Cure times will be very fast.

RK-1500 Two-Part, No-Mix, High Strength Liquid Acrylic Adhesive is used in a variety of areas and industries around the world. Some of it’s known uses include:

Please note Polyamide, PTFE and polyolefin may only be bonded after special treatment of the surface (e.g. low-pressure plasma, corona, flame impingement).

| Basis | Methyl Methacrylate (MMA) |

|---|---|

| Colour After Curing | Yellowish - Transparent |

| Density of the Mixture | 1 g/cm³ |

| Viscosity of the Mixture | 4,500 MPa |

| Application Procedure | No Mix |

| Composition | Pasty |

| Handing Strength (35% of Final) | 5 Minutes |

| Capable of Bearing Mechanical Loads (50% of Final) |

8 Minutes |

| Processing Temperature | +10°C to +40°C |

| Curing Temperature | +18°C |

| Fully Cured (100%) | 24 Hours |

| Adhesive Gap Bridging | 0.4mm – 0.8mm |

| Temperature Resistance (After Curing) |

-50°C to +130°C (+180° Short-Term) |

| IMPA Code | 81 29 92 |

| ISSA Code | 75.629.53 |

| Shear Strength (According to DIN 53281) | |

| Aluminium | 20 N/mm² |

| Sand Blasted Steel | 25 N/mm² |

| Stainless Steel | 30 N/mm² |

| Polycarbonate | 10 N/mm² |

| PMMA | 8 N/mm² |

| ABS | 6 N/mm² |

| Hard PVC | 11 N/mm² |

| Fibreglass Reinforced Polyester | 20 N/mm² |

| Fibreglass Reinforced Epoxy | 27 N/mm² |

| Polyamide 6.6 | 3 N/mm² |

| SKU | SWM000223B01 |

|---|---|

| Brand | Weicon |