Welcome to the second of four posts dedicated to helping you choose the best super glue for different types of plastic. We’ll be publishing one per week for the next four weeks.

Welcome to the second of four posts dedicated to helping you choose the best super glue for different types of plastic. We’ll be publishing one per week for the next four weeks.

This week is part 2 and deals with choosing a super glue for different types of plastic. This follows last weeks 1st part in which spoke about how to identify different types of plastic. Over the next two weeks, we'll also cover preparing the plastic for bonding (now available here) and applying the glue, along with tips for achieving maximum bond strength (available here).

For those of you who need to super glue plastic now, and don’t really feel like waiting for the next few posts, please do not hesitate to contact us, we’ll be happy to help in the meantime. Alternatively, our comprehensive guide to super glues is also available. It doesn’t focus on plastic exclusively, but does contain a wealth of information that could be very helpful in guiding your glue choice.

Choosing a Super Glue for your Plastic.

At this point, you hopefully have a good idea of what kind of plastic you need to bond. With this information, it is now possible to select the best super glue for your bonding job.

At this point, you hopefully have a good idea of what kind of plastic you need to bond. With this information, it is now possible to select the best super glue for your bonding job.

Are you sure you want a super glue?

Before getting into the glues available and which one you need, a quick point on the benefits and limitations of super glue. Super Glues (aka Cyanoacrylate Adhesives, Instant Adhesives or Cyanos) are one-part, cold-curing adhesives that set fast and hard. They are great for bonding small surfaces with high strength, they are not so great in some other bonding areas.

Below is a brief overview of their strengths and weaknesses. If your bonding job lines up more with super glues weaknesses, please do let us know as there are many other adhesives our there to compensate for this and we can assist in helping you find the right one. For everyone else, read on for guidance on picking the best super glue for your plastic bonding.

| Strengths | Weaknesses |

|

Fast Bonding High Strength Wide Material Compatibility Simple To Use (No Mixing) Economical |

Large Surface Areas High Temperatures Blooming Joint Movement Fumes While Curing |

Surface Energy

Surface Energy

Before we contine, a quick primer (sorry!) on the fundamentals of adhesion and the concept of surface energy.

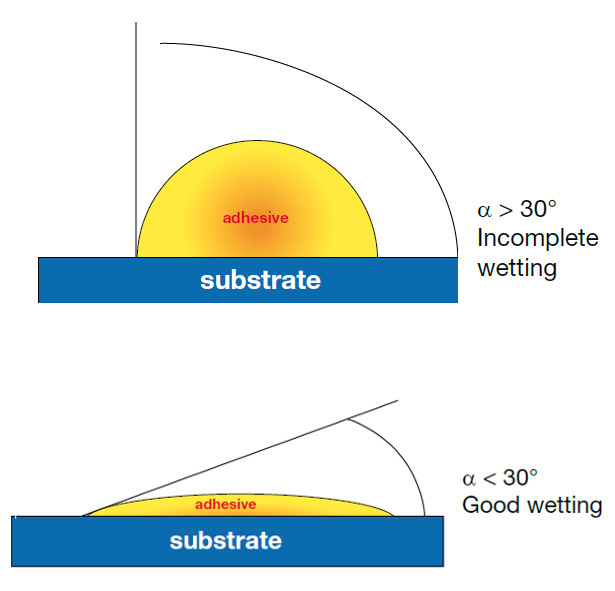

Low surface energy is quite a technical concept that affects the degree of attraction between unlike material molecules (in this case, the glue and the plastic). Simply put, the higher the surface energy of a particular material, the greater its attraction to dissimilar materials. The lower the surface energy, the weaker the attractive force.

Higher surface energy results in increased contact between an adhesive and the material it is applied to. Put another way, a high surface energy plastic (like Nylon) will allow the adhesive to flow or “wet” the plastic and therefore create a stronger bond.

This principle can perhaps best be explained by an example. Think of your car. When it has been waxed recently, raindrops will naturally bead into small droplets on the surface. This is because the waxed surface has low surface energy and is therefore repelling the water. Conversely, if you haven’t waxed your car in a while (and I can relate to this), raindrops will spread out to form larger puddles. This is because the un-waxed surface has higher surface energy and therefore increased molecular attraction allows the water to flow.

Apologies for the diversion, but the concept of surface energy appear many times in the sections below so, I believe, it was worth getting a quick intro out of the way now (you can also read a lot more about the subject here). With that accomplished, let’s move onto identifying our best super glues for different types of plastic.

Super Glues for PET Plastic (Recycling Code 1)

PET, or Polyethylene terephthalate plastic, is quite difficult to bond. This type of plastic is characterised by its low surface energy. Most commercially available cyanoacrylates will struggle to form high strength bonds with this material; even those marketed as “super glues for plastic”.

Our range is no exception. While several of our glues will bond, using them by themselves will result in a bond strength of only around 45% of their usual maximum. For some applications, this will be ok. For those that require a higher strength bond, we recommend the use of our CA Primer for Polyolefins.

By combining one of the glues below with this primer, you will be effectively changing the surface of the plastic so that it better accepts the adhesive. This will result in a higher strength bond. Typically, bond strength on PET will increase by about 50% compared to joins made with just the glue.

Like I said, not critical for all applications but if you really need a high strength join and must use super glue (we do have some other specialised options) then one of the glues below, plus our CA Primer is really the way to go.

| Grade | Characteristics | Summary | Link |

| VA 8312 |

|

A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. | Click Here |

| VA 8406 |

|

Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Good with PET when used with the primer. Ideal for when super-fast adhesion is required. | Click Here |

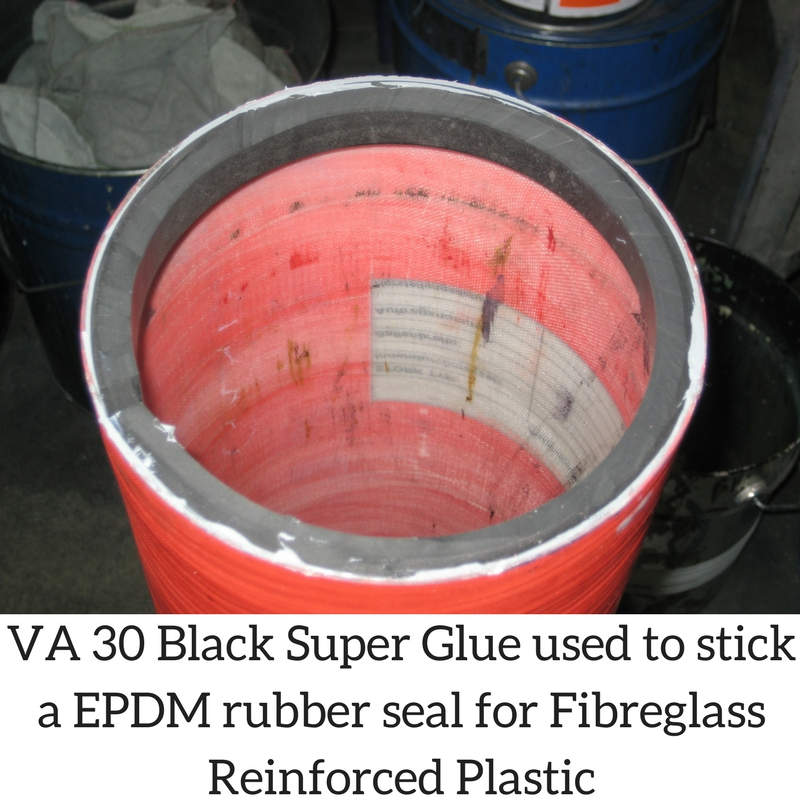

| VA 30 |

|

VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). VA 30 should only be used on PET along with a primer. | Click Here |

This list will expand as we add more and more glues to our range.

Super Glues for HDPE and LDPE Plastics (Recycling Codes 2 & 3)

Both High Density Polyethylene (HDPE) and Low Density Polyethylene (LDPE) are characterised as very low surface energy plastics. Just like PET, bonding HDPE & LDPE with any old super glue will likely result in a very weak bond (or no bond at all). Even those super glues marked as “suitable for plastic” will likely struggle unless they specifically mention their compatibility with polyethylene.

Both High Density Polyethylene (HDPE) and Low Density Polyethylene (LDPE) are characterised as very low surface energy plastics. Just like PET, bonding HDPE & LDPE with any old super glue will likely result in a very weak bond (or no bond at all). Even those super glues marked as “suitable for plastic” will likely struggle unless they specifically mention their compatibility with polyethylene.

Once again, our industrial strength super glue range is not an exception to this rule. Several of our glues will bond, but they will not achieve the full shear strength listed on their specification sheets when used with HDPE or LDPE. Typically, they’ll achieve about 45% of this listed number, but this will vary depending on the exact type of polyethylene your working with, surface prep and other factors.

For some applications, 45% of a very high strength bond will be perfectly fine. If that’s the case for your application, using one of the cyanoacrylates listed below without a primer is viable. For everyone else, a primer will be required.

Our CA Primer for Polyolefins modifies the surface of polyethylene and makes it more conducive to bonding. This primer can be used in conjunction with any of the glues listed in the table below, and will typically result in a 50% increase in the bond strength that would have been achieved if you used just the glue alone.

| Grade | Characteristics | Summary | Link |

| VA 8312 |

|

A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. | Click Here |

| VA 8406 |

|

Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Should be used with the primer for HDPE or LDPE. Ideal for when super-fast adhesion is required. | Click Here |

| VA 100 |

|

VA 100 is a universal type of industrial super glue. It will bond well to most plastics, though it definitely should be used in conjunction with the primer for HDPE or LDPE. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. |

Click Here |

| VA 30 |

|

VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

This list will expand as we add more and more glues to our range.

Super Glues for PVC Plastic (Recycling Code 3)

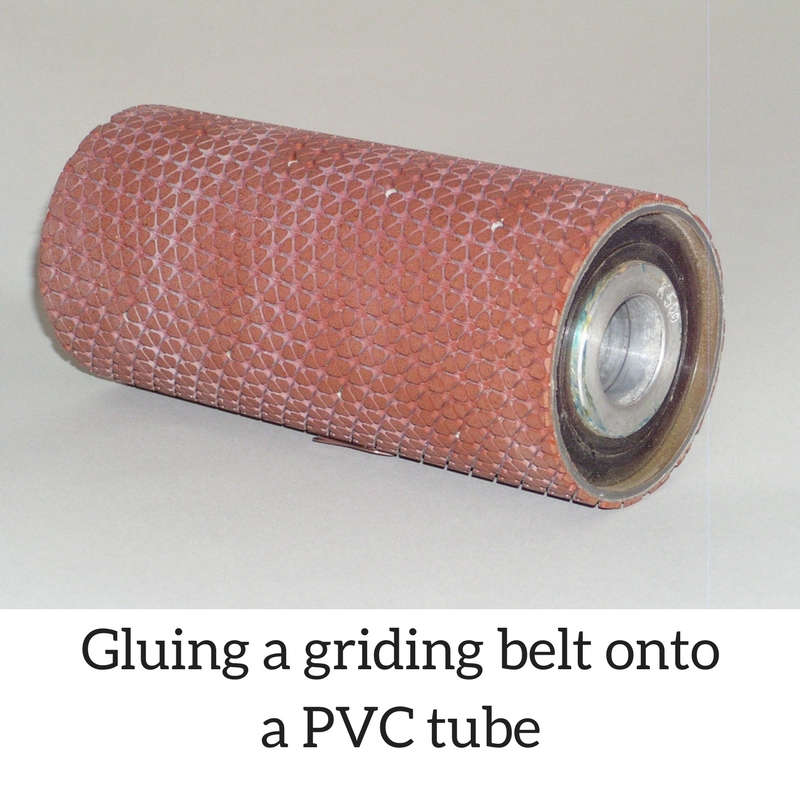

PVC (Polyvinyl Chloride) is a high surface energy plastic and is very compatible with super glues. Each of the glues listed in the table below will adhere well to PVC and form a strong bond. For the vast majority of bonding applications, no primer will be required when gluing PVC as the glue itself will work just fine.

PVC (Polyvinyl Chloride) is a high surface energy plastic and is very compatible with super glues. Each of the glues listed in the table below will adhere well to PVC and form a strong bond. For the vast majority of bonding applications, no primer will be required when gluing PVC as the glue itself will work just fine.

That said, it is still necessary to ensure that you properly prepare the surface before bonding and, also, consider the type of PVC you are working with. For rigid or solid PVC sheet, both a low viscosity (runny) or high viscosity (thicker) type of super glue will be ok. If you’re wanting to glue PVC sponge, or some other porous type of PVC, a thicker cyanoacrylate will be preferable in most situations.

| Grade | Characteristics | Summary | Link |

| VA 8312 |

|

A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. | Click Here |

| VA 8406 |

|

Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. | Click Here |

| VA 100 |

|

VA 100 is a universal type of industrial super glue. It will bond well to rigid PVC, handle a slightly larger bonding gap than VA 8406 or VA 8312 and be a better choice for more porous types of PVC (like closed cell sponge). It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. | Click Here |

| VA 30 |

|

VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

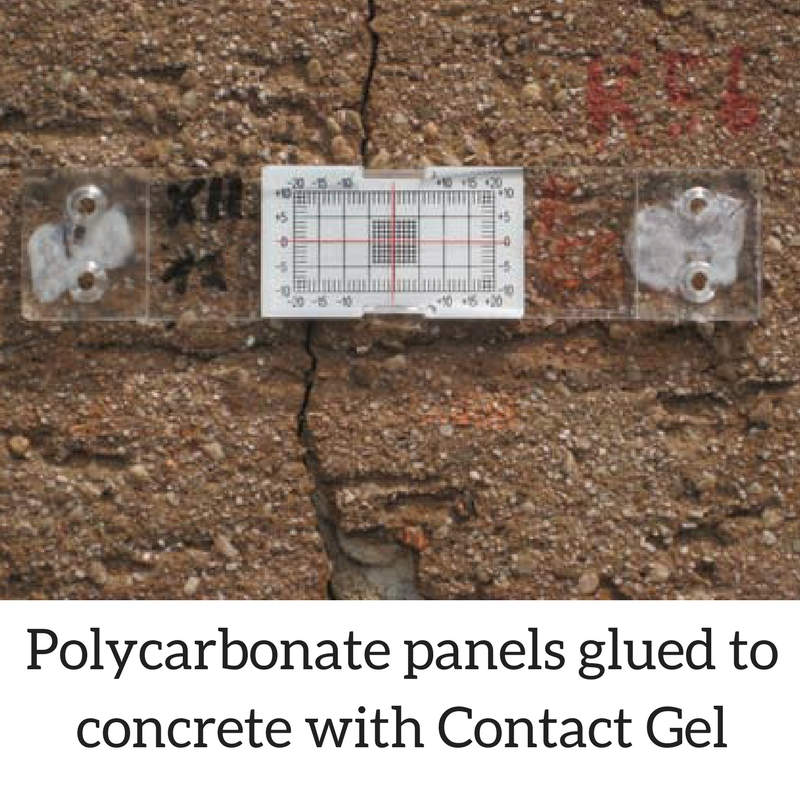

| Contact Gel |

|

Contact Gel is a thick, pasty type of super glue. It will bond to many types of PVC and is good for sticking porous materials like sponges and foams. It cures at a far slower rate than those listed above, which allows you a little time to reposition the parts being bonded if required. | Click Here |

This list will expand as we add more and more glues to our range.

Super Glues for Polypropylene and PTFE (Teflon®)

Together, Polypropylene and PTFE (Polytetrafluoroethylene, better known by the brand name Teflon®) are two of the most difficult materials to bond. PTFE in particular is known for its very low friction; hence the reason it’s used as a coating on things like non-stick fry pans.

Together, Polypropylene and PTFE (Polytetrafluoroethylene, better known by the brand name Teflon®) are two of the most difficult materials to bond. PTFE in particular is known for its very low friction; hence the reason it’s used as a coating on things like non-stick fry pans.

While bonding these materials with super glue is difficult, it is not impossible.

Both sit near the bottom of the surface energy table, with polypropylene being even lower than polyethylene, and PTFE being lower again. Unsurprisingly, to glue either of these materials you will not only need a high-quality contact adhesive, but an advanced primer.

The glues below, used in conjunction with our CA Primer for Polyolefins will bond PTFE or Polypropylene. For Polypropylene, you can expect a bond strength of roughly 60-70% which would be achieved on PVC. PTFE is less, around 40%, but still strong enough for many applications.

Short of etching the PTFE or using some other form of high grade, specialised adhesive (like an MMA), these super glues in conjunction with the primer represent one of the most reliable methods for bonding these incredibly tough, hard to bond materials. Surface preparation is key so please do ensure you follow all steps outlined on your chosen adhesives data and safety sheets.

| Grade | Characteristics | Summary | Link |

| VA 8312 |

|

A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Should only be used on PTFE or Polypropylene along with a primer. | Click Here |

| VA 8406 |

|

Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. VA 8406 may achieve some, low-strength bonds on Polypropylene by itself (though a primer is suggested for higher strength requirements). On PTFE, a primer is always suggested. | Click Here |

This list will expand as we add more and more glues to our range.

Super Glues for Polystyrene (Recycling Code 6)

Super Glues for Polystyrene (Recycling Code 6)

Polystyrene is a plastic that has a low surface energy. Many types of super glue may struggle with it, but not all. Super glues made specifically for plastic bonding, or those designed for industrial-grade work, like our Weicon range, are usually compatible with polystyrene and will create good, strong bonds.

The glues listed in the table below are known to work well with most types of polystyrene. Once again, the exact form the plastic takes is important. If you are working with expanded polystyrene or a polystyrene foam, it will be best to choose a higher viscosity grade of glue. Solid polystyrene allows greater flexibility in selection and you should get good results with either the low, medium or high viscosity adhesives.

| Grade | Characteristics | Summary | Link |

| VA 8312 |

|

A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Good with solid polystyrene, not great with expanded polystyrene due to its viscosity. Ideal for applications where initial adhesion is required very, very fast. | Click Here |

| VA 8406 |

|

Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. It's still not great with expanded polystyrene, but could work in a pinch (especially at lower bonding temperatures). It is very good with solid polystyrene and is ideal for when super-fast adhesion is required. | Click Here |

| VA 100 |

|

VA 100 is a universal type of industrial super glue. It will bond well to most plastics and polystyrene is included in this. It is not as runny (higher viscosity) as VA 8312 or VA 8406 which makes it better suited for expanded polystyrene. It is a good choice if you are looking for a slightly extended cure time. | Click Here |

| VA 30 |

|

VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

Super Glues for other, common types of plastic (Recycling Code 7 or N/A)

ABS

ABS plastic (Acrylonitrile Butadiene Styrene) is a very common form of plastic used in everything from Lego bricks to 3D printers. It is a high surface energy plastic that works well with most types of super glue.

Our range of cyanoacrylates will all work fairly well in bonding ABS, while those in the table below will work exceptionally well.

When sticking ABS, you can expect any of the below super glues to achieve a bond strength (measured according to DIN 53283 standards as shear strength) that is quite similar to that achieved with rigid PVC and very similar to performance on polycarbonate. For all but the most demanding of bonding jobs, no primer is required. Any of the below glues by themselves will create high strength bonds.

| Grade | Summary | Link |

| VA 8312 | A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Maxium temperature rating (once cured) is 80°C. Will bond well to ABS without the need for a primer. | Click Here |

| VA 8406 | Ideal for when super-fast adhesion is required. Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312, but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. VA 8406 will bond well to ABS without the use of a primer. | Click Here |

| VA 100 | VA 100 is a universal type of industrial super glue. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time.. | Click Here |

| VA 30 | VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

| Contact Gel | Our Contact Gel super glue is a thick, pasty type of adhesive. This glue has an extended cure time, is very pasty and is good for covering larger bonding gaps, or for use on vertical surfaces. Contact Gel works fairly well with ABS plastic and will withstand temperatures of up to 80°C once it is fully hardened. | Click Here |

This list will expand as we add more and more glues to our range.

Polycarbonate

Polycarbonate

Polycarbonate is one of those plastics that is far more commonly known by one of the trademarks based on it. These include plex-i-glas and Lexan. Usually clear, Polycarbonate (PC) is a high surface energy plastic that is fairly straight forward to glue.

Most types of Polycarbonate on the market will work well with super glues designed for plastic. The table below lists a number of such options, all of which will achieve good, strong bonds without the need for an additional primer.

Expected shear strength of the bond is usually roughly in line with that achieved on ABS, and only slightly below that with rigid PVC.

| Grade | Summary | Link |

| VA 8312 | A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Maxium temperature rating (once cured) is 80°C. Will bond well to Polycarb without the need for a primer. | Click Here |

| VA 8406 | Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. VA 8406 will bond well to Polycarb without the use of a primer. | Click Here |

| VA 100 | VA 100 is a universal type of industrial super glue. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. | Click Here |

| VA 30 | VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

| Contact Gel | Our Contact Gel super glue is a thick, pasty type of adhesive. This glue has an extended cure time, is very pasty and is good for covering larger bonding gaps, or for use on vertical surfaces. Contact Gel works fairly well with most types of polycarbonate and will withstand temperatures of up to 80°C once it is fully hardened. | Click Here |

This list will expand as we add more and more glues to our range.

Nylon

Nylon

Nylon isn’t actually a type of plastic. Rather, it is a name given to a group of very similar plastics that are based on either semi-aromatic or aliphatic polyamides. As a result, writing about the potential for super glue to work with Nylon can be a little tricky as we’re really talking about a collection of different plastics each with their own specific properties.

In general, Nylon and super glues will work ok together. Nylons are usually quite high in surface energy (though I really must stress some specific grades are not) and therefore accept wetting from the glue quite well. This allows you to achieve fairly good, high strength bonds using just a high quality, compatible glue without the need for a primer.

Each of the super glues listed below will work with most types of Nylon without a primer. Used by themselves, you can expect to achieve a bond strength in the range of 75% of that which would be achieved with rigid PVC. Since the PVC bond is so strong, 75% of that is often fine for most applications.

If you would like to increase the bond strength further and still use a super glue, our CA Primer for Polyolefins will help.

| Grade | Summary | Link |

| VA 8312 | A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Maxium temperature rating (once cured) is 80°C. | Click Here |

| VA 8406 | Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. | Click Here |

| VA 100 | VA 100 is a universal type of industrial super glue. It will bond well to most types of Nylon. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. | Click Here |

| VA 30 | VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

| Contact Gel | Our Contact Gel super glue is a thick, pasty type of adhesive. This glue has an extended cure time, is very pasty and is good for covering larger bonding gaps or for use on vertical surfaces. Contact Gel works well with many grades of nylon and will withstand temperatures of up to 80°C once it is fully hardened. | Click Here |

This list will expand as we add more and more glues to our range.

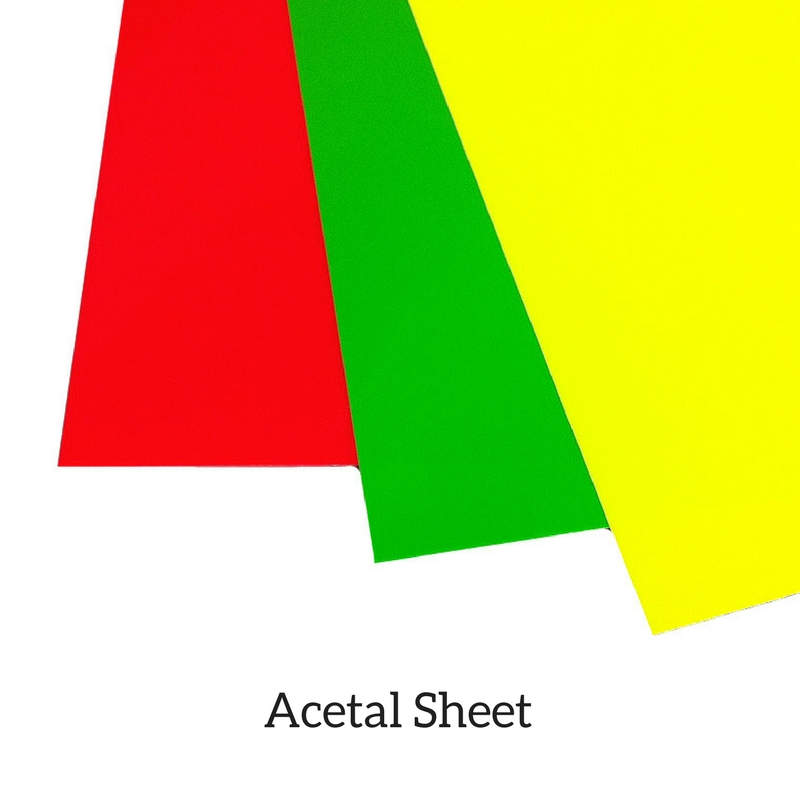

Acetal

Acetal

Acetal, also known as polyacetal and by the more technical Polyoxymethylene and Polyformaldehyde, is a type of plastic known for its low friction surface. Unsurprisingly, it has a low surface energy and can be quite challenging to bond with super glues.

Generally, Acetal sits somewhere between Polystyrene and Polyethylene in terms of surface energy (though specific brands and grades may differ). When it comes to choosing a super glue for this type of plastic, there are two options.

General purpose super glues aren’t likely to work well with Acetal. Even generic ones that claim to be “for plastic” might struggle and I would be suspicious of any that don’t specifically list acetal as a material they are capable of bonding with.

If a relatively low strength bond will be ok for what you’re doing, the glues listed below by themselves should be ok. Using these cyanoacrylates by themselves should result in a bond strength that is about 45% as achieved with rigid PVC.

If you require a higher strength bond, you’re going to need to use a primer. By combining one of the glues below with our Contact Primer for Polyolefins, you will increase the shear strength of the glue by about 85%. This enables high strength gluing of acetal parts.

| Grade | Summary | Link |

| VA 8312 | A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Maxium temperature rating (once cured) is 80°C. | Click Here |

| VA 8406 | Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. VA 8406 will bond Acetal without a primer, but bond strength will definitely be increased if one is employed. | Click Here |

| VA 100 | VA 100 is a universal type of industrial super glue. It will bond well to most plastics, though it should be used in conjunction with the primer for Acetal. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. | Click Here |

| VA 30 | VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). VA 30 should only be used on Acetal along with a primer. Bonding may occur without in some applications, but the strength of the bond is likely to be limited. | Click Here |

This list will expand as we add more and more glues to our range.

Polyester Resin Based Materials

Polyester Resin Based Materials

Like Nylon, Polyester isn’t really a plastic but rather a group of similar polymers. These can include naturally occurring chemicals or synthetic ones. Consequently, the compatibility of Polyester with super glues varies depending on the exact type being bonded.

One of the most common types of Polyester is Polyethylene Terephthalate (PET) which was covered earlier in this post. Another popular type is Polyester Laminate which usually refers to a solid, rigid sheet that consists of polyester resin that is reinforced with fibreglass. It goes by quite a few names including GRP (Glass Reinforced Polyester), FRP (Fibreglass Reinforced Polyester), numerous brand names (including Glastic) and in the electrical industry, things like GPO3.

Though each specific grade and type will differ, most polyesters will have a reasonably high surface energy (somewhere around ABS is common). This makes them fairly straight forward to bond with super glue. You will want to ensure you use a cyanoacrylate made for plastics, but the use of a primer typically isn’t required.

Each of the glues in the table below should work very well with polyester resin based materials. Though this depends on specific application conditions, you can usually expect a bond made with these to achieve about 90% of the strength it would exhibit if used with rigid PVC.

| Grade | Summary | Link |

| VA 8312 | A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Maxium temperature rating (once cured) is 80°C. VA 8312 will work well with most types of Polyesters. | Click Here |

| VA 8406 | Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. VA 8406 will bond well to most types of rigid polyester sheets and parts. | Click Here |

| VA 100 | VA 100 is a universal type of industrial super glue. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. VA 100 has good compatability with Polyester based materials and is widely used on these without a primer. | Click Here |

| VA 30 | VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

| Contact Gel | Contact Gel super glue is a thick, pasty type of adhesive. This glue has an extended cure time, is very pasty and is good for covering larger bonding gaps, or for use on vertical surfaces. Contact Gel works well with many grades of polyester and will withstand temperatures of up to 80°C once it is fully hardened. | Click Here |

This list will expand as we add more and more glues to our range.

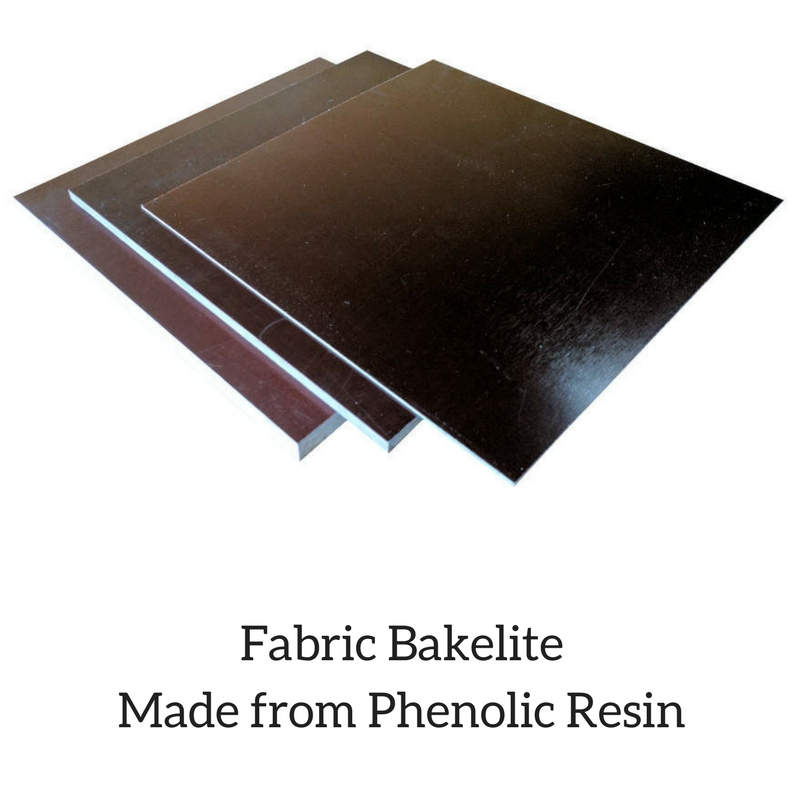

Phenolic

Phenolic

Phenolic resins, also known as Phenol formaldehyde resins (PF), are used to make many different plastics. Usually, they are combined with some other material (such as paper or fabric) for reinforcement, then set to form a hard, rigid type of plastic sheet. By far, the most common on these is Bakelite.

Bakelite is a tough, rigid type of plastic and usually has a smooth surface finish. Despite this, it exhibits high amounts of surface energy and can be reliably bonded with super glues without an additional primer.

As was the case with the polyester resin based plastics, sheets made with phenolic resin are best bonded using a super glue designed specifically for plastics rather than a commercial, general purpose glue.

All of the super glues in the table below will bond well to most forms of Bakelite (and other phenolic resin based plastics) without the need for a primer. Usually, the bond strength achieved will be around 75% of that observed with rigid PVC.

| Grade | Summary | Link |

| VA 8312 | A colourless, clear liquid. VA 8312 is quite runny and best used on rigid plastics and for gluing parts that will fit together very closely. Ideal for applications where initial adhesion is required very, very fast. Maxium temperature rating (once cured) is 80°C. VA 8312 will work well on phenolic materials without a primer. | Click Here |

| VA 8406 | Similar to VA 8312. VA 8406 is a colourless glue that is slightly less runny than VA 8312 but is still very fluid-like. Best for rigid plastics and parts that will fit together closely. Ideal for when super-fast adhesion is required. Works very well on phenolic materials and does not require a primer to create high strength bonds. | Click Here |

| VA 100 | VA 100 is a universal type of industrial super glue. It is not as runny (higher viscosity) as VA 8312 or VA 8406 and is a good choice if you are looking for a slightly extended cure time. VA 100 has been shown to work well on Phenolic materials and achieve good, strong bonds. | Click Here |

| VA 30 | VA 30 is a special kind of super glue. It is black in colour, withstands high temperatures (140°C continuous) and has good residual elasticity, impact resistance and the ability to withstand changing climate conditions (e.g. humidity). It is also good for covering slightly larger gaps than many glues (up to 0.2mm). | Click Here |

| Contact Gel | Contact Gel super glue is a thick, pasty type of adhesive. This glue has an extended cure time, is very pasty and is good for covering larger bonding gaps, or for use on vertical surfaces. Contact Gel works well with phenolics and is a good choice for precision placement of glues parts. It will withstand temperatures of up to 80°C once it is fully hardened. | Click Here |

This list will expand as we add more and more glues to our range.

.jpg) Advice for plastics not listed and sources for more information.

Advice for plastics not listed and sources for more information.

Of course, not every plastic is listed in this guide. We’ve tried our best to be as comprehensive as possible but with so many on the market, and so many variations on a theme between plastic manufacturers, a truly comprehensive list is likely impossible.

If the type of plastic you need to bond is not listed here, please do not hesitate to contact us. We’re in constant contact with the manufacturers of our adhesives and together with our own knowledge and experience, should be able to find a solution for you.

Also, if you have any other tips or tricks for super gluing plastic, don’t be shy and leave them in the comments. That way others will get the benefit of your experience and we’ll be able to incorporate this extra information into even better guides in the future.

We hope you have enjoyed this second part of our series on choosing a super glue for plastic. If you did miss it, Part 1 on Identifying Different Types of Plastic is available here. Next week we’ll publish the third part of our guide which covers ways to prepare the surface for bonding (now posted and available here). We hope you’ll check back for that and, once again, if we can be of any further assistance please don’t hesitate to let us know.

Other Posts in this Series on Our Best Super Glues for Plastic

Part 1: Tips and Methods for Identifying Different Types of Plastic

Part 3: Preparing the Plastic Surface for Bonding

Part 4: Applying the Glue and Tips for Maximum Bond Strength

Comments (1)

Gluing solution required

Swift Supplies response

Leave a comment