BULK DISCOUNT RATES

| Buy 3 - 5 | and pay only $125.07 each |

| Buy 6 or above | and pay only $118.43 each |

| Buy 3 - 5 | and pay only $125.07 each |

| Buy 6 or above | and pay only $118.43 each |

Our Weicon Crack Testing Dye Penetrant Flaw Identification Kit is a specially engineered solution for finding small surface flaws. It has been developed by Weicon in Germany and is designed to be easy to use yet highly reliable.

This kit includes one can of each of the following sprays:

Together these allow you to reliably test and inspect all kinds of different materials and objects. The system works using a dye-penetration method and is non-destructive. More specifically, this kit works especially well with…

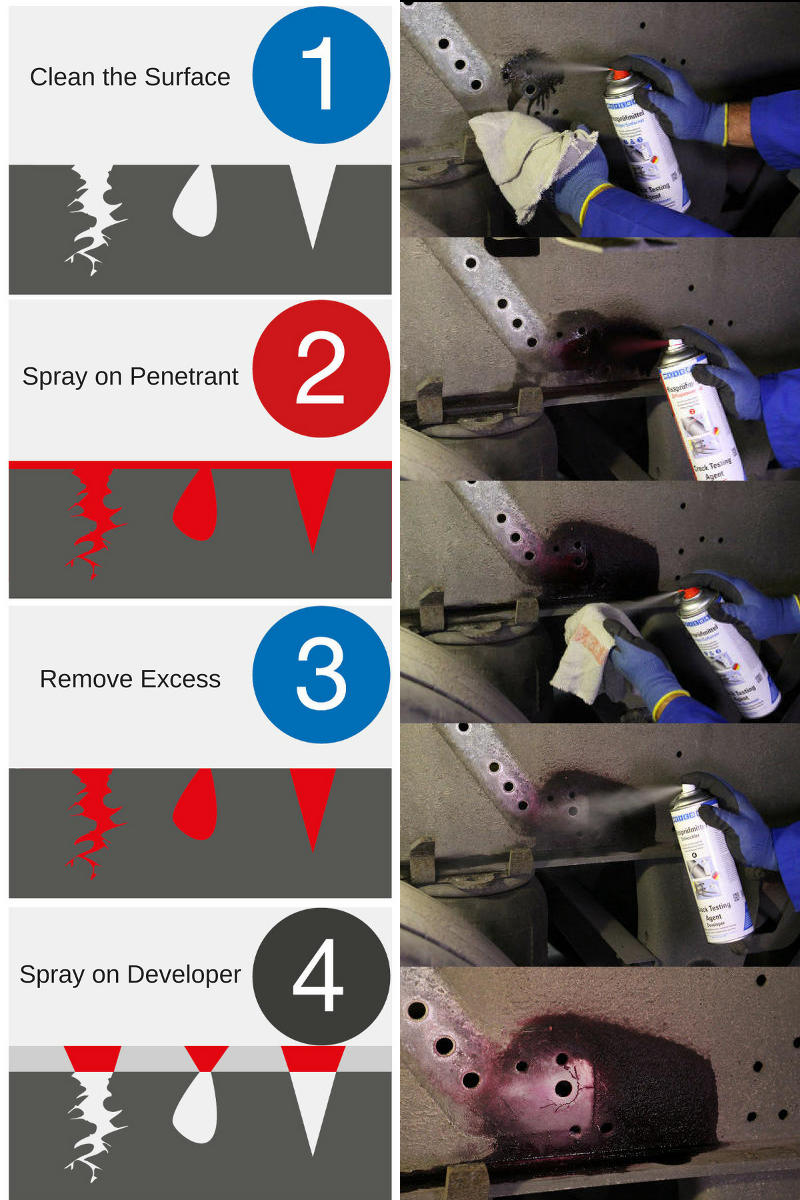

How to use our Crack Testing Dye Penetrant Flaw Identification Kit.

How to use our Crack Testing Dye Penetrant Flaw Identification Kit.There’s a simple, 4-step process involved in finding flaws with this kit.

Using the Crack Testing Agent Cleaner, clean the surface that will be tested. This industrial-grade cleaning spray is fast acting and very easy to use. It cleans dirt, oil, dust and other types of soiling that could otherwise affect the test. It also evaporates without leaving behind any residues which results in less clean-up.

Grab the can of red, penetrating colour and spray the testing area. This technical spray has excellent penetrating properties which enables it to help identify even the smallest cracks, fissures and faults before they become bigger problems.

Once you’ve allowed a little time for the penetrant spray to work its way into any cracks, remove the excess with a quick clean using the included cleaning spray. This will make finding any flaws far simpler in the next step.

The final step in the process; spraying on the developing agent. Once sprayed, the Developer will create a white background surface while cracks, flaws or problems will remain red. Our Crack Testing Developer Spray only needs to be used sparingly and is very effective.

Once you’ve applied the developer, we suggest performing a visual inspection of the surface after about 5 to 10 minutes.

We are pleased to offer this professional-quality Crack Finding System both as a complete kit and as individual sprays. The kit is available directly from this page and contains 1 can of Cleaner, Penetrant and Developer. Links are included below, via which, you can buy each spray individually.

|

|

|

|---|---|---|

| Cleaning Spray | Penetrant Spray | Developer Spray |

| Cleaner | Penetrant | Developer | |

| Colour | Colourless | Red | White |

| Scent | Solvent | Solvent | Solvent |

| Minimum Shelf-Life | 24 Months | 24 Months | 24 Months |

| Temperature Resistance | 0°C to +50°C | 0°C to +50°C | 0°C to +50°C |

| SKU | SWM000250B01V0001 |

|---|---|

| Brand | Weicon |