BULK DISCOUNT RATES

| Buy 3 or above | and pay only $41.80 each |

| Buy 3 or above | and pay only $41.80 each |

Our pipe repair kits are fast, simple and easy to use options for sealing leaks or repairing cracked piping. Manufactured in Germany, these kits consist of a two-part system comprised of our Steel Repair Stick and a resin-impregnated tape.

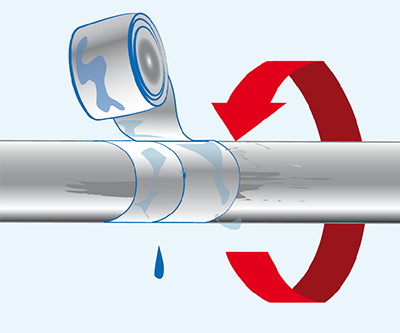

The Repair Stick putty is easy to mix and apply by hand before setting hard. The tape is highly flexible and can be easily wrapped tight around bends and odd shapes. Once it is wet with water, it will begin to harden to form a solid, lasting wrap.

The sections below describe the various features of this system along with more information on how to use it to repair all kinds of pipes. The video available above (or via the media tab) also provides a quick demonstration.

Each pipe repair kit is supplied with the following:

1 x Steel Repair Stick.

1 x Resin Impregnated Fibreglass Tape (3 Sizes Available).

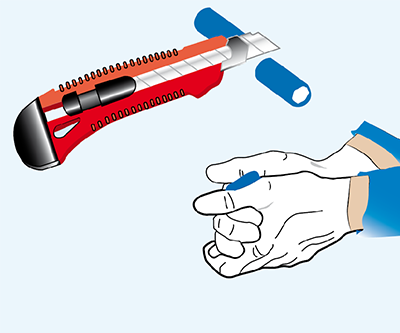

A pair of gloves and assembly instructions.

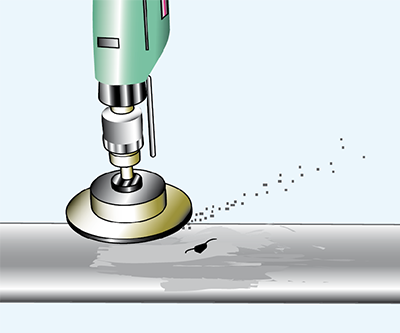

You won’t need any additional tools to fix pipes with this kit. The Repair Stick can be mixed by hand. All you’ll need is something to roughen the surface if possible and water to activate the tape.

Our pipe repair kits have been designed for maximum versatility and can be used on almost all types of piping and ducting. These repair kits are compatible with:

They can be used on dry or wet areas and even applied underwater.

Our Weicon Pipe Repair Kits are industrial grade solutions that withstand demanding operating conditions. They offer excellent chemical and pressure resistance and are able to withstand exposure to continuous temperatures up to 120°C with short-term spikes to 150°C (the tape can handle this permanently).

Our Pipe Repair Kits are used in all kinds of industry areas around the world. These fast, permanent solutions are often used in plant maintenance work in the oil & gas sectors, power generation, chemical processing and food & beverage manufacturing. Basically, anywhere there is a large amount of pipe work that needs to be maintained and, occasionally, repaired.

Because of the highly flexible nature of the putty and tape combination, Pipe Repair Kits are often chosen for repair work on hard to access areas or for repairs around T-pieces, bends or junctions.

All sizes of Weicon Pipe Repair Kits have been certified in accordance with NSF ANSI 61 for use in food and beverage applications.

These Pipe Repair Kits are designed to be very easy to use. They require no special tools and limited surface preparation. The steps below outline how the system works (instructions are also included with each kit) while the video linked at the top of this page also provides a good overview.

|

|

|

|

|

| Remove Pressure from the Pipe | Roughen the Surface | Portion and Knead the Repair Stick | Apply Repair Stick to Leak | Dip Repair Tape into Clean Water |

|

|

|||

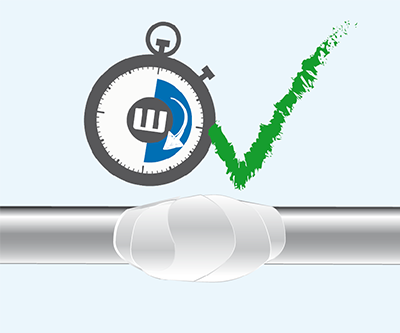

| Wrap around the Pipe and Moisten the Tape | Wait 30 Minutes for the Tape to Fully Cure |

Though neither are a required step, we do often find the additional options presented here can be of benefit.

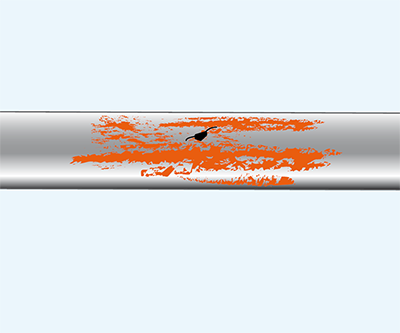

The first has to do with corrosion protection. One of the most common causes of pipe damage is rust so it makes sense that when you’re repairing the pipe, it might be a good opportunity to also protect against further corrosion. Our Weicon Zinc Spray is ideal for this.

Once you’ve applied the repair stick to the leak, spraying over the top with Zinc Spray will help to seal. This industrial quality, cold-galvanising spray will form a long-lasting protective layer that protects against rust. It has a high zinc content, is fast-drying and is made using microfine zinc flakes (rather than pellets) for outstanding rust prevention.

Obviously, we only suggest this option for metal pipes. It’s of no benefit whatsoever if using the pipe repair kit on plastic piping. It’s also impractical if repairing piping underwater.

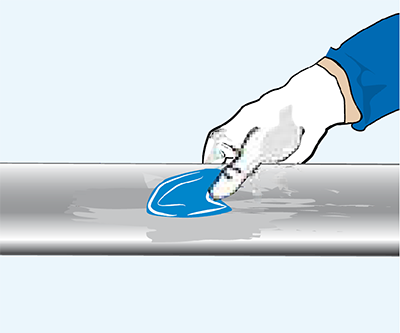

Another finishing option that can sometimes be of benefit is the application of a final, protective layer of Ceramic BL Plastic Metal. This high-quality epoxy coating will provide an additional sealing layer and sets very hard with excellent abrasion resistance to protect the pipe and repair work.

Ceramic BL can be brushed on and has excellent temperature and chemical resistance. In the demonstration video mentioned earlier, it’s the blue compound you see being applied towards the end of the process.

| Colour | Dark Grey (Once Cured) |

|---|---|

| Continuous Operating Temperature | -50°C to 120°C |

| Short-Term Operating Temperature | 150°C (2 Hours Maximum) |

| Maximum Gap Filling | 15mm |

| Basis | Epoxy Resin with Steel Fillers |

| Density | 2 g/cm³ |

| Pot Life (for 25gm at 20°C) | 4 Minutes |

| Handling Strength (35% of Final) | 10 Minutes |

| Mechanical Strength (50% of Final) | 60 Minutes |

| Final Strength (100%) | 24 Hours |

| Shore Hardness | 75 Shore D |

| Dielectric Strength | 3 kV/mm |

| Colour | White |

|---|---|

| Continuous Operating Temperature | +150°C |

| Pot Life (at 20°C) | 3-5 Minutes |

| Composition | Polyurethane |

| Final Hardness (100%) | 30 Minutes |

| Tensile Strength | 35 N/mm² |

| Compressive Strength | 150 bar |

| Shore Hardness (ASTM D 1706) | 70 Shore D |

| SKU | SWM000306B01 |

|---|---|

| Brand | Weicon |